How it works

Click on – and + to see the focus control

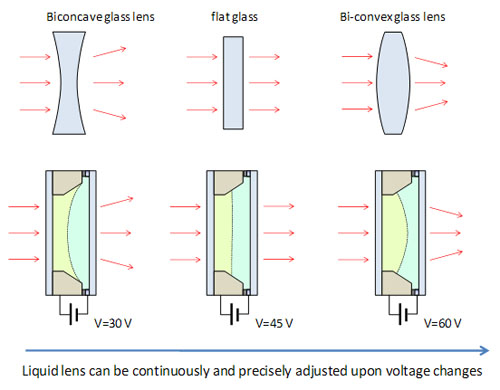

The focus control changes continuously by an electrical command through the electrowetting principle.

ElectrowettingFor centuries scientists have combined lenses of very different optical powers, from diverging lenses to highly converging ones, to design and manufacture complex optical instruments. Until now the optical properties of all these lenses, either made from glass or plastic and typically requiring months to be produced, were always fixed. Varioptic has now created a « smart lens » that can be reconfigured on demand with just a variation of voltage. The lens can adapt rapidly and continuously from diverging to converging and be modeled to support all key optical functions, starting with Auto-Focus and Optical Image Stabilization. The technology uses the principle of "Electrowetting" and a combination of transparent and optically defect-free liquids to create a lens and change its characteristics in real time. Liquids have been used since 40 years in optical systems for high-end products such as goggles or camcorders but Varioptic's innovation is to have created a real-time programmable platform that offers to change the shape of the liquids in a very fast, repeatable, precise and controlled way. |

|

Main advantages of liquid lenses:

- Large range of optical variations:

Displacing a liquid interface allows large phase shifts variations, more than 200 waves in a typical "Arctic" lens, where typically liquid crystals or other adaptive systems are limited to about 10 waves. When used in focus variations, that means for instance 40 diopters (10 times the eye accommodation) over a 3mm diameter aperture.

- Robustness:

Liquid lenses have been tested for over 30 millions cycles without any performance degradations, while mechanical systems such as piezo, motors and VCM (Voice Coil Motors) are typically limited to a few hundred thousand cycles.

- Shock resistance:

Under drop tests Liquid lenses behave much better than mechanical solutions like VCM. Repeatability of LL response curve is excellent before, and after shock tests. In a VCM system the lens is suspended to a soft spring, resulting in offset positions changing after every shock, causing increasingly degraded focus performance.

- Speed:

Liquid reconfiguration can be as fast as tens of milliseconds. These time scales are well adapted to human interfaces, video, photo capture etc…

- Low power consumption:

Liquid Lenses will typically dissipate about 15mW, driver included, about 10 times lower than VCM, piezos or motors.

- Design flexibility:

One can change at will the diameter of the liquid lens, the zero-voltage value of the optical power, the index of fluids, the range of dioptric corrections as well as the position of this range regarding to an offset position.

- Programmability:

Camera module manufacturers can use liquid lens for AF and benefit also from free-focus integration to suppress costly individual adjustment during manufacturing.

Liquid Lens Applications

Electrowetting enables to manipulate the liquid interface shape, in order to create various optical functions or optical corrections.

Possible applications of liquid lenses are too many and too diverse to be all mentioned, but the list below can serve as a starting point for innovative thinking for new products, new applications or improved performance.

Digital imaging applications:

- Very fast image capture

- Very fast AF mode (non sequential algorithms)

- Capturing multiple images at different focus positions, from infinity to 3cm object.

- Reconstruct a 3D map from captured depth information

- Correct for handshake in real time

- Super-resolution, zoom

- Laser focusing XYZ (AF+OIS liquid lens)

- Laser de-cohering

- Wave front corrections (adaptive optics, ophtalmology)

- Light dispersing for illumination

- Longitudinal spectrometry

- Feedback loops for fine optical adjustments

- Active control of beam deviations

Non-imaging applications:

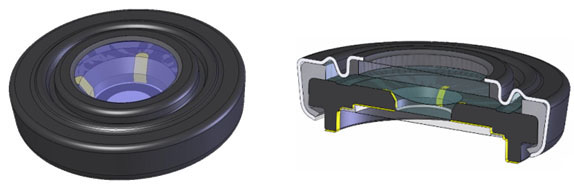

Multiple liquid lens configurations in a single body

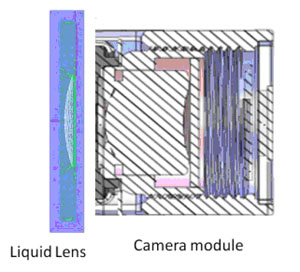

The flexibility of liquid lens packaging allows having a single external body for several products, allowing very high flexibility in product design and evolution:

Varioptic liquid lens external packaging

Inside the liquid lens, the different optical functions can be produced using different designs with specific electrodes patterns and different liquids

A few examples:|

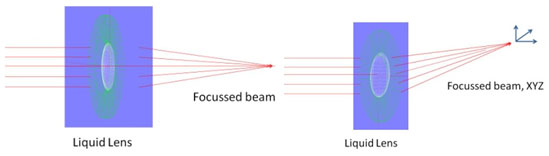

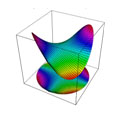

Single electrode lens: Liquid interface is a sphere, changing radius as a function of voltage |

Quad-Electrode lens: the liquid interface is a sphere of adjustable radius and arbitrary tilts |

Multiple electrode lens: With eight electrodes, the liquid interface can include Zernike corrections for: • Sphere • Tilt • Cylinder (or astigmatism) |

|

|

|

| Fast focusing of the light for imaging or beam control applications | Fast focusing and tilting of the light beam for XYZ control of the optical rays. |

Electrowetting: A voltage variation induces a change in the contact angle of the fluid and effectively creates a lens with the precise desired properties.

In the drawing below, Electrowetting is explained in a very basic configuration: a drop of oil is deposited on a planar surface , made of a flat electrode covered with a thin insulating and hydrophobic layer, all this being immersed in a water based conducting liquid. Voltage is applied between the flat substrate electrode and another electrode dipped in the conducting liquid (not shown on the photographs).

|

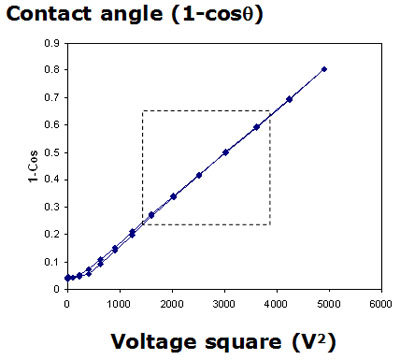

A basic experiment enables to measure very accurately the contact angle versus voltage shown on the curve below: |

The curve shows the drop shape variation as a function of voltage during a voltage cycle. The dotted square shows the region of interest in a liquid lens. This basic experiment emphasizes two important characteristics of the Electrowetting fluid actuation: linearity (precision) and reversibility (or hysteresis free). Both are key for making a liquid lens, in addition to a number of other suitable design choices.